Kodak Enhances Vision3

A new anti-halation system offers a variety of technical and environmental improvements while maintaining the film stock’s high image quality.

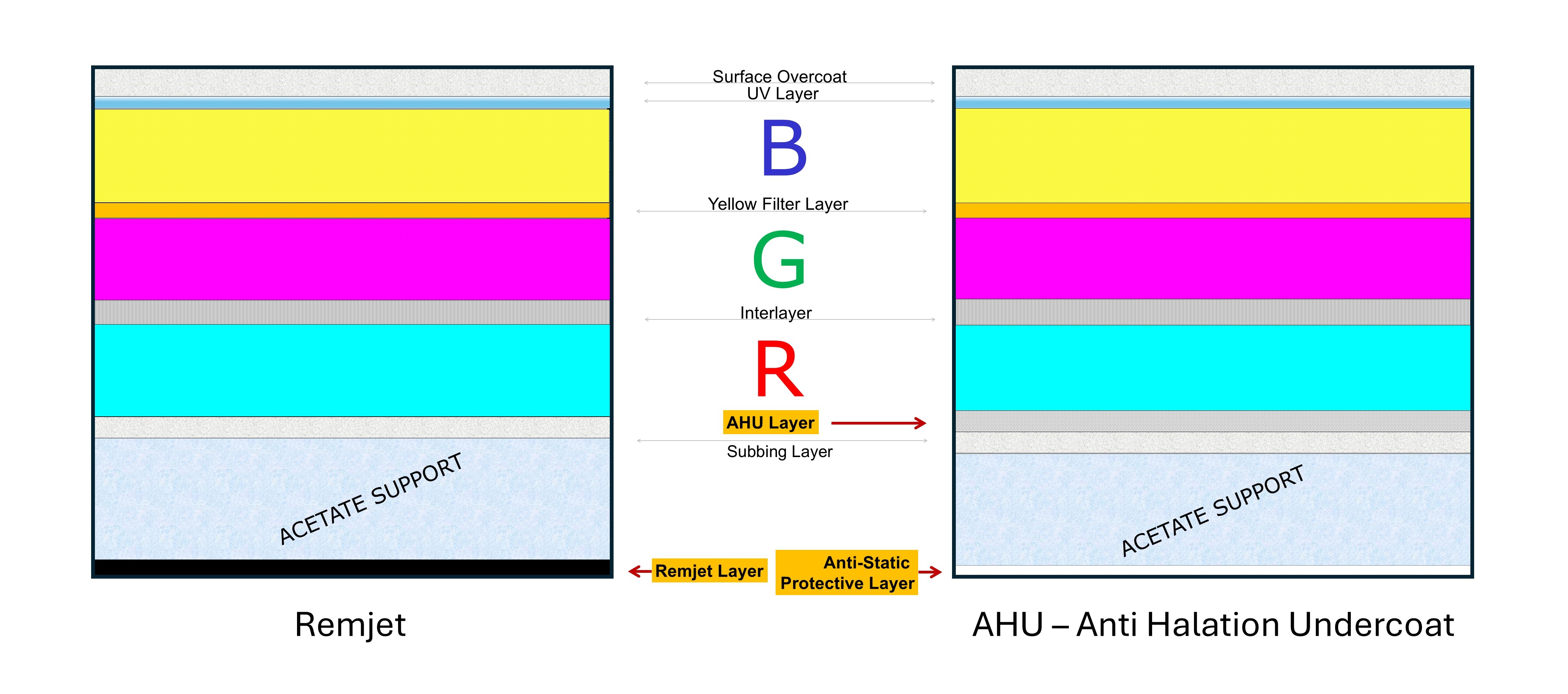

Kodak has introduced a redesign of its Vision3 motion-picture color-negative films, removing the disposable, carbon-based remjet backing and replacing it with an advanced anti-halation technology, appropriately called Anti-Halation Undercoat (AHU).

The new film stock has already been used on a number of feature films and short-form projects, including an untitled A24 film directed by Jesse Eisenberg and “Fame Is a Gun,” a music video featuring Addison Rae that was directed and shot by Sean Price Williams.

“We’re excited to formally announce the new AHU film structure — after years of R&D and successful customer implementation across all Vision3 film codes and formats,” says Vanessa Bendetti, Kodak’s vice president and head of motion picture. “AHU offers an improved and more environmentally conscious product, while allowing filmmakers to continue to optimize the intrinsic values of Vision3. The investment in and success of this project is testimony to Kodak’s commitment to its film business, and the dedication of those who make our film in Rochester, New York.”

The change is significant. Remjet, invented by Kodak in 1934, was previously coated onto the base layer and was designed to prevent static and scratches and to control halation — those bothersome light halos. But there were drawbacks. After removal of remjet during processing, the film lost its anti-static layer and was prone to collecting dirt. The removal of the remjet also created a muck that would challenge development baths and required separate tanks for motion-picture film (as opposed to still film stock).

However, the new technology more easily cuts down on static and performs scratch resistance while still combating halation without the need for remjet. Most importantly, AHU covers all Vision3 film stocks (5/7219, 5/7213, 5/7207, and 5/7203), and will be implemented across all formats, from Super 8 to 65mm.

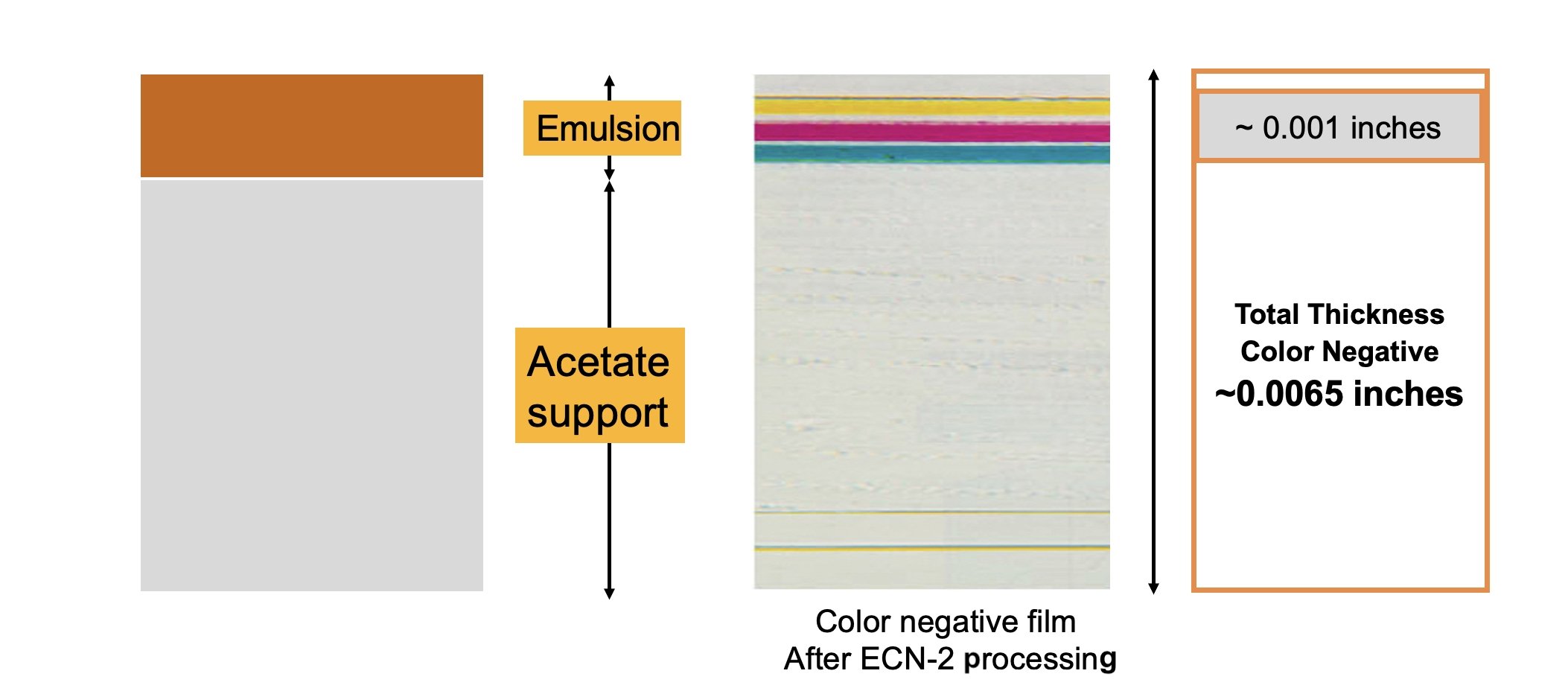

The AHU stocks fall within the 5-micron range of low-to-high tolerances for remjet Vision3 thickness, with a differential of just 2 microns, a figure Kodak regards as immaterial. It incorporates an anti-static backside layer that survives the developing process and minimizes the accumulation of dust and dirt during scanning, along with an emulsion-side halation-protection layer. Meanwhile, AHU, unlike the black-hued, matte-finish remjet, is dark brown with a glossy appearance.

AHU is a gel-based layer that is coated beneath the emulsion layers of the film. It is manufactured as part of the emulsion-coating process and contains silver and other chemical components, which have been scientifically balanced for optimal sensitometric performance. AHU, which is also conveniently removed during processing, requires no workflow adjustments for processing, scanning or printing.

The new product also offers environmental advantages for labs. It is expected that water and energy usage will be drastically reduced with the elimination of remjet, which required more extensive pre-bath wash processes. Kodak estimates that photochemical labs around the world will collectively reduce water consumption by millions of gallons per year, pre-bath chemical solutions by more than 50,000 gallons per year, and energy use up to 100,000 kWh annually.

More than eight years in the making, these enhancements have been achieved through rigorous research and testing by Kodak’s film design and manufacturing teams in Rochester. They started by building on foundational work done in the early 2000s. Approximately 45 multi-layer pilot coating experiments were performed between 2016 and 2018.

However, as a result of the pandemic between 2019 and 2022, Kodak tabled AHU efforts until the program was restarted in 2023. Since then, Kodak updated the original AHU layer design and reformulated it for each of their stocks.

Internal testing and customer trials revealed that AHU offers superior halation protection and more reliable and cleaner results from the additional anti-static layer. In addition, the silver-based layer for halation protection was chosen for several advantages: It’s easily removed during standard motion-picture processing; it’s proven technology from consumer films (still-photography products); the location of the AHU layer provides improved image quality; the advanced technology can include an antistatic layer on the backside of the film that survives developing; and AHU offers greater halation control than previous technologies.

Of particular interest to filmmakers is that Kodak has established new catalog numbers for each Vision3 AHU film product. This is an internal requirement, and the remjet catalog numbers will slowly be phased out. However, the trade names of each Vision3 product will remain the same (with the addition of “AHU” in the catalog).

In sum, Kodak asserts that AHU offers filmmakers a more robust and environmentally friendly version of Vision3 with the same high image quality of its photographic performance.

Kodak is still in the final stages of its rigorous commercialization process for the new film structure, and AHU volume will be limited for the foreseeable future as Kodak’s manufacture of remjet product is phased out.

This edition of Tools of the Trade originally appeared in American Cinematographer's September 2025 issue. Learn more here about how to subscribe to the industry's leading journal of motion-picture production techniques.

Image and diagrams courtesy of Eastman Kodak Co.